System Effectiveness

Efficiency and reliability are two requirements that work together to meet your expectations

Efficiency and reliability are two requirements that work together to meet your expectations

Economics measured by energy savings and maintenance cost savings operations

Measure and verify the optimization of the systems not just on the first day, but every day

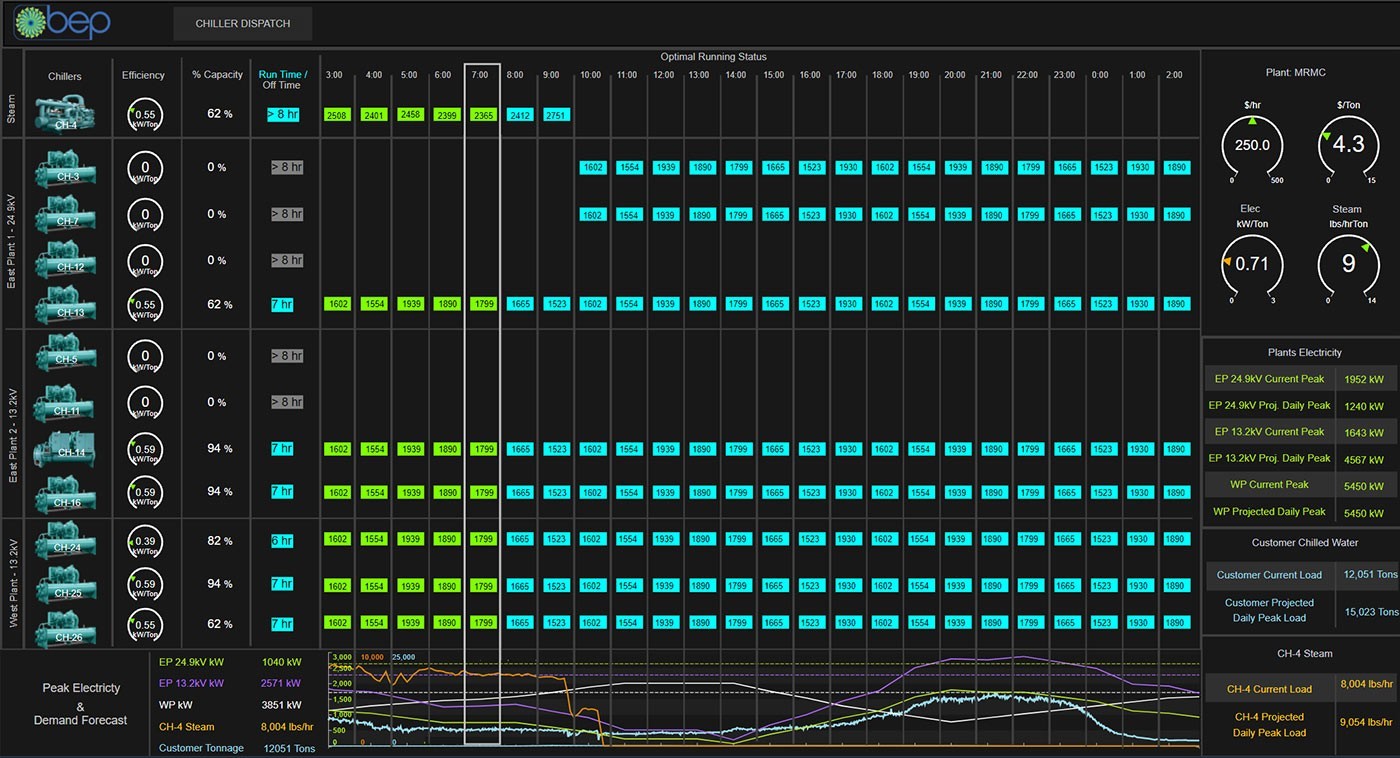

Our advanced forecasting and dispatching engine optimizes your Chilled Water plant with sophisticated predictive analytics.

Our exclusive way of monitoring systems ensures performance when optimization matters.

Getting what you expect should be the standard not the exception.